Lotion Pump Production Line

We provide the complete pump production line.

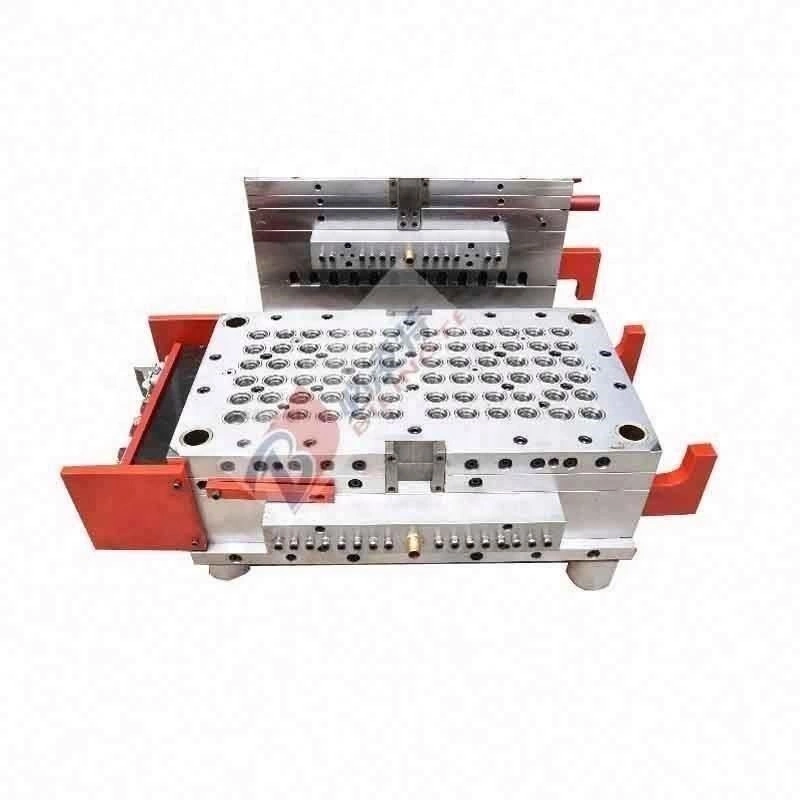

| Mold Material | S136 | No. Of Cavities | 2, 4, 8, 16, 32, 48 or more |

| Mold Base | P20 Steel | Guarantee Mold Life | 2000000 shots |

| Injection Gate | Hot Runner | Delivery Time | 45-65 working days |

| Packing | Wooden box | Plastic Products Samples | Provide fress |

Plastic Lotion Pump Mould Main feature

1. Multi-cavity lotion pump mould design and tooling abilty

2. High speed injection cycle time

3. Fast & optimal cooling system design for lotion pump mould

4. Moldmax material application in mould core & cavity

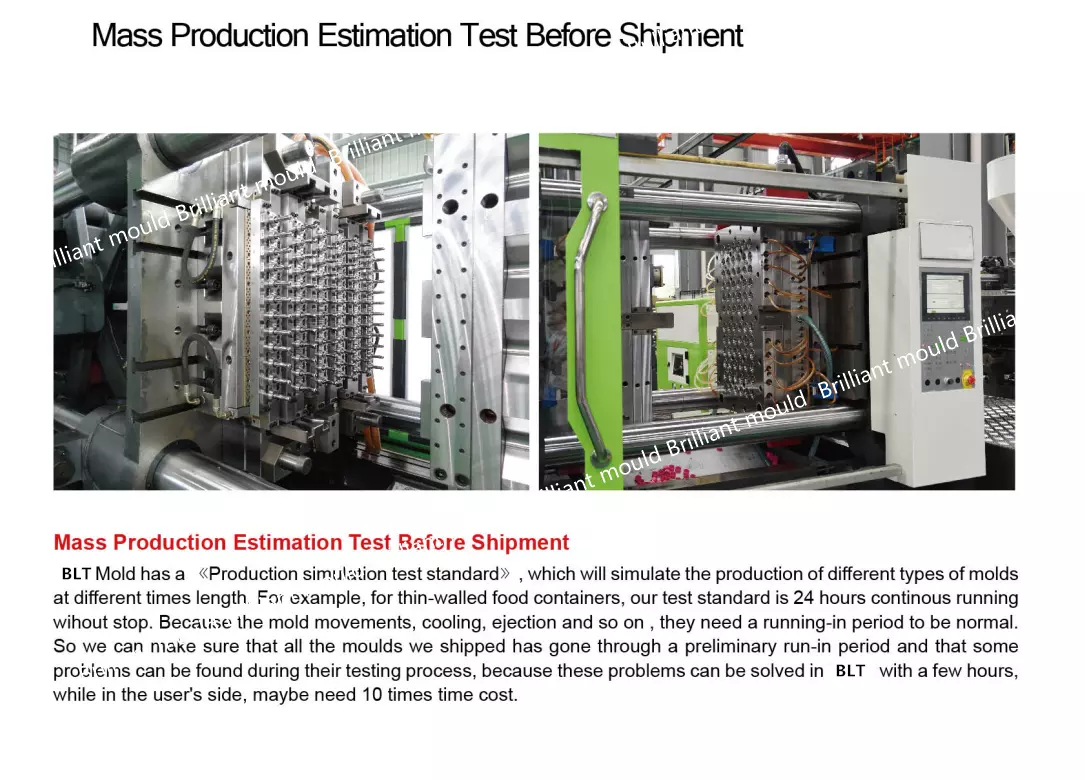

Mass Production Estimation Test Bafore Shipment

Brilliant Mould has a《Production simulation test standard》, which will simulate the production of different types of molds at different times length. For example, for lotion pump mould, our test standard is 24 hours continous running wihout stop. Becalise the mold movements, cooling, ejection and so on , they need a running-in period to be normal. So we can make sure that all the moulds we shipped has gone through a preliminary run-in period and that some protiems can be found during their testing process, because these problems can be solvedin Brilliant with a few hours, while in the user's side, maybe need 10 times time cost.

Precision Tooling Equipment

All of lotion pump mold parts are manufactured by CNC equipments.

Independent cooling system of each cavity to ensure the size consistency, temperature-control box included,

Standard interchangeable mold components, Send samples to customers for inspection.

Our workers are fully qualified and skilled at using modern production techniques. Computerized CNC (Computer Numeric Coordinates) Systems (CAD/CAM) produce newmolds with money-saving speed and accuracy. We employ a wide range of manual, automatic and computerized equipment in making moulds.

Lotion Pump Mould Produce Process

1. Design 2D 3D lotion pumps' drawings and confirm with customers;

2. Design 2D 3D lotion pump moulds' drawings and confirm with customers;

3. Produce lotion pump molds;

4. Write the mold production progress report to customers every week;

5. The mold production is completed and will make the first mold trial;

6. If there is no problem with the product, mail the lotion pump sample to the customer for confirmation;

7. If there is the problem with the product, repair the mold and make mold trial again;

8. Mail the sample to the customer, and the customer confirms the sample;

9. Deliver lotion pump mold.

Current Location:

Current Location: